Data loggers for validation and routine monitoring

Medicine - Pharma - Food

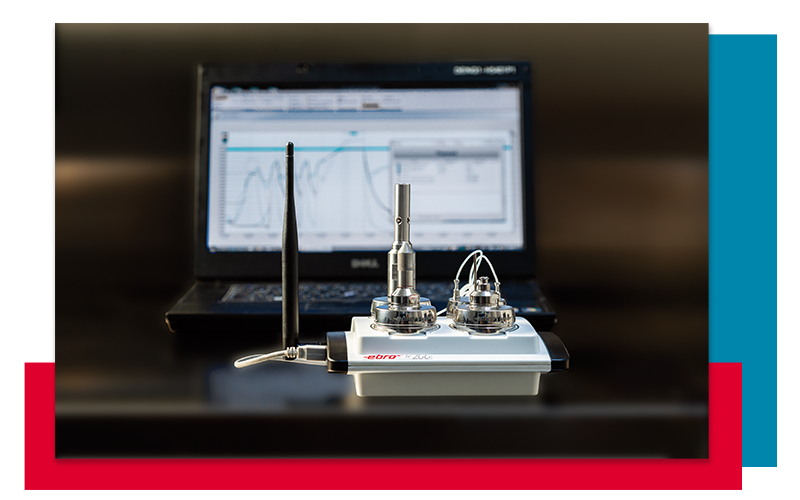

Continuous monitoring of physical parameters such as temperature, pressure, or relative humidity with data loggers

Medicine

The validation of reprocessing processes is regulated in Germany in §8 MPBetreibV(1): "The reprocessing of medical devices intended for use in a low-germ or sterile state must be carried out using suitable validated procedures, taking into account the manufacturer's specifications, in such a way that the success of these procedures is comprehensibly guaranteed and the safety and health of patients, users or third parties is not endangered." Furthermore, proper reprocessing of medical devices is assumed if the recommendation of the RKI "Hygiene requirements for the reprocessing of medical devices" is observed. Important standards for the validation of cleaning and disinfection processes are the standards DIN EN ISO 15883 and DIN 58341, as well as the standard DIN EN ISO 17665-1 for steam sterilization processes.

Pharma

In the pharmaceutical environment, the term "validation" takes into account the requirements of Annex 15 of the Good Manufacturing Practice (GMP) guidelines and FDA regulation 21 CFR Part 211. It refers to the formal process of demonstrating and documenting that a pharmaceutical manufacturing process or system is capable of producing consistent results that meet quality requirements, safety standards and regulations. This includes the validation of manufacturing equipment, processes, systems, methods and controls. It is critical to ensure the integrity and quality of pharmaceuticals and to ensure compliance with regulatory requirements.

Food

Process control in the food industry refers to the systematic monitoring and control of manufacturing processes to ensure that food products are produced in accordance with established quality standards and safety regulations. This process involves the continuous monitoring and measurement of factors such as temperature, pressure, humidity, pH, time, pasteurization units and other relevant parameters that affect the manufacturing process. The data collected is analyzed to ensure that the process meets the desired production requirements, and that product quality is consistent. For process control in the food sector, the data loggers used must be food-safe.

What are data loggers?

Depending on the application and type of use, ebro® offers the right data logger for you.

In many areas of the manufacturing industry, continuous monitoring of physical variables such as temperature, pressure or relative humidity is essential.

With a data logger as a special measuring device, relevant measured values can be permanently recorded and evaluated, which can be easily transmitted and clearly displayed thanks to modern computer technology.

Classic variants such as bottle loggers for determining the temperature of various liquids make production and quality control much easier. Other variants, such as PDF data loggers, help to automatically create documents for presenting the measured values. Our product range includes a variety of modern data loggers whose functions and technical features cover a wide spectrum of business and industry.

Find out more now!

As a manufacturer of high-quality and reliable data loggers, it is our task to advise you on all important issues before you purchase the data loggers. You should be able to select the right logger for your application and be sure that it will continue to function as desired in the future.

Arrange a free consultation

with one of our experts!

New brochure:

"On the safe side with validated processes"

Product information about data loggers,

certificates,

technical data etc.

Data loggers FAQs

Here you will find answers to frequently asked questions.

How do data loggers work?

From bottle loggers to pressure gauges, modern data loggers are similar in design. All models have one or more sensors that measure the desired physical parameter at regular intervals and record the measured value in an internal memory or transmit it directly to a receiver.

The interface of modern measuring devices is always digital and enables data transmission via radio or explicit readout as a USB data logger. The evaluation and presentation of the recorded data is carried out using specialized software, so that a professional evaluation of the measured data can be carried out on almost any PC. If it becomes apparent that the measured values have exceeded the specified limit values or that the cold chain has been interrupted during transportation, the software can issue a corresponding warning.

With simpler loggers, the focus can be purely on determining the measured values without direct transmission and evaluation, so that it must be read out as a USB data logger at a later time, for example.

What are typical features of data loggers?

Data loggers are designed to measure and record specific physical values so that they can then be transferred to a computer in real time or after a set interval. The type of measured values determined in this way depends entirely on the sensor of the data logger. Data loggers have different properties depending on the desired application:

- If data loggers are intended to indicate compliance with certain transportation conditions, such as temperature, humidity, etc., at first glance, this is sometimes done with a simple "OK" or "not OK" display on the logger. These loggers usually fulfill their task as "single use" loggers and are discarded after transport.

- If data loggers are used for routine monitoring, they are usually not removed but read on site via their display or the values are transferred to software in real time. This makes it possible to alert the user and intervene in a timely manner.

- Data loggers for extreme conditions, such as in autoclaves or heating ovens, are built without a readable display in order to withstand the high temperatures. These measuring devices are usually used for very limited time intervals and are read out retrospectively.

What components does a data logger consist of?

Data logger: The data logger itself is the central part of the system. It contains sensors for data acquisition and electronic circuits for signal processing. The data logger stores the recorded data either internally or on external storage media.

Sensors: Sensors are devices that record physical parameters such as temperature, humidity, pressure, conductivity or other measured values. They are connected to the data logger via cables or wireless connections and provide continuous measurement data.

Power supply: Data loggers require a reliable power supply. This can be provided by batteries, power from the mains or other energy sources.

Storage media: Data loggers store the recorded data on internal memory or on external storage media such as SD cards, USB drives or cloud services.

User interface: Most data loggers have a user interface that allows the logger to be configured, data to be displayed and settings to be made.

Software: Accompanying software allows the data logger to be configured, data to be displayed in real time and stored data to be analyzed.

Accessories: These include brackets, protective housings, cables, and mounting elements, which are required depending on the application.

Which standards and which processes are covered?

Data loggers for validation and routine monitoring in the medical sector must meet specific requirements. Our data loggers meet the requirements of the following standards:

ISO 17665, ISO 15883, ISO 11140-4, EN 285, EN 13060

Our data loggers can be used to monitor the processes in the following devices, among others:

Steam sterilizers, plasma sterilizers, FO sterilizers, washer-disinfectors, washer-disinfectors for endoscopes, DAC, careclave

What is validation?

In the medical and pharmaceutical field, validation refers to the process of demonstrating that medical devices, production facilities, processes and procedures meet established standards and requirements and provide consistent, reliable and safe results.

This validation process is critical to ensure the quality, efficacy and safety of medical devices and pharmaceutical products. It involves comprehensive assessment, documentation and verification of compliance with regulations and quality standards at every stage of development, manufacture and use.

Validation can include aspects such as the sterility of medical devices, the efficacy of pharmaceuticals, the accuracy of diagnostic equipment and process control in pharmaceutical production facilities. Validation ensures that products do not cause harm to patients and users and provide the intended medical benefit.

What is calibration & adjustment?

Calibration and adjustment of data loggers are important procedures to ensure that these devices provide accurate and reliable results.

Calibration refers to the comparison of data logger readings with known reference values to detect and correct inaccuracies. This process ensures the accuracy of measurements and is particularly important in applications where precise data is critical.

Adjustment refers to the process of adjusting data loggers to ensure that they operate in accordance with their specifications. It is a process of fine-tuning where the data logger is returned to its original state. This may be necessary if the data logger drifts or provides incorrect measurements.

Functions & Requirements

The specifications for data loggers vary depending on the application. It is important to consider the specific requirements of your application and select a data logger that meets these standards. In the following, we take a closer look at the most important properties of a data logger:

Data acquisition

Data loggers should be able to collect data from sensors or data sources. This may include temperature, humidity, pressure, conductivity or other parameters.

Accuracy

Data loggers should provide accurate and precise measurements that meet the requirements of the specific application.

Customization

The configuration should be customizable so that recording intervals, alarms and other parameters can be set according to requirements.

Memory & Security

Data loggers must provide sufficient storage space for the data collected to ensure that the data can be stored for the required period of time. Security features and encryption are important to protect collected data from unauthorized access.

Power supply

Data loggers should have efficient power manageability features and the ability to replace batteries or be powered by other means.

Robustness

Data loggers should be able to withstand the environmental conditions in which they are used. This includes, for example, resistance to dust, moisture and temperature tolerance.

User-friendliness

The operation and configuration of the data logger should be user-friendly to ensure easy setup and usage.

Analysis

The ability to manage and analyze data is helpful in identifying trends and patterns. This can be done on the device itself or in the associated software.

Our bestsellers

Whether for monitoring pasteurization units or validating sterilization processes, only data loggers with high accuracy and robustness meet the requirements of the relevant standards for reliable and reproducible process safety.

Robust and versatile data loggers with easy handling

EBI 12 Series

Compact data loggers for use in limited space

EBI 11 Series

Easily evaluable data loggers for transport with a USB plug

EBI 300 Series

Automatic data loggers with alarm function for storage and cooling

EBI 25 Series

Which data logger is right for you?

This depends on the intended application.

- For transportation we recommend the loggers of the EBI 300/EBI 310/EBI 330 family, as these can be read out via the USB port on any PC without an additional interface or software.

- For routine checks in hospitals, we recommend the EBI 12 or EBI 16 data loggers for checking steam sterilizers, washer-disinfectors, RDGs or bedpan washers or for the electronic Bowie and Dick test in autoclaves.

- For validation we recommend the data loggers of the EBI 12 and EBI 11 family, as they are versatile and offer extremely high accuracy in the measuring range relevant for validation.

- For refrigerator or storage monitoring we recommend the loggers of the EBI 25 family, as these automatically ensure compliance with the temperature limits and send an e-mail in the event of an alarm, so that you are also warned of problems at the weekend.

- In the industrial sector the EBI 40 is mainly used as up to twelve thermocouples can be connected to it. Due to the different sensors available for the logger, it can be used for almost any application (for example: Surface measurement, measurement in the product or in liquids).

Find out more now!

As a manufacturer of high-quality and reliable data loggers, it is our task to advise you on all important issues before you purchase the data loggers. You should be able to select the right logger for your application and be sure that it will continue to function as desired in the future.

Arrange a free consultation

with one of our experts!

New brochure:

"On the safe side with validated processes"

Product information about data loggers,

certificates,

technical data etc.

Why ebro®?

ebro® is part of Xylem Analytics and a leading provider of professional measurement technology for the food, medical, pharmaceutical and industrial sectors.

Certified service provider

- ISO 9001:2015

- Accreditation according to DIN EN ISO/IEC 17025:2018

- EC declarations of conformity

- TÜV certificate of the Winlog.validation software via DIN ISO/IEC 25051:2014, DIN EN ISO 9241-110:2020 and FDA 21 CFR part 11

Our service advantages

- Calibration according to ISO and DAkkS in Germany

- International service and field service

- 30 years of experience in the sale and servicing of sterilization loggers

- Support with IQ & OQ thanks to documentation and service

- Customized training courses at the CompetenceCenter

Online Shop

Do you already know what you need? Then choose one of our best-selling products here and you will be taken directly to our online shop

Overview

Data loggers

- Robust, versatile and compact

- Measurements:

- Temperature: -200 °C … +400°C

- Pressure: 1mbar … 10.000 mbar

- Relative humidity:

0 % rF … 100 % rF - Conductivity:

1 μS/cm … 2000 μS/cm - Interval 1 s ... 24 Std.

Data loggers

for validation

- EBI 11 & 12

- Highly accurate & robust

- Reproducible proof

- Temperature, pressure, humidity

- Automatic evaluation

- FDA conform

- Factory calibration certificate

Data loggers

for routine monitoring

- EBI 11 & EBI 16

- Periodical measurements

- Temperature, pressure, humidity

- Automatic evaluation

- AEMP

- Bowie-Dick

- Factory calibration certificate

Data loggers

for cold chain monitoring

- EBI 20, 25, 300

- Complete cold chains

- High accuracy

- Continuous measurement

- GMP mapping

- Easy handling

- Factory calibration certificate

Contact

Xylem Analytics Germany Sales GmbH & Co. KG, ebro

Peringerstr. 10, 85055 Ingolstadt, Germany